Tesla's 12V system, vital for lighting, audio, and control modules, requires understanding batteries, alternators, fuses, and relays for effective repairs. Common issues include dead battery starts, flickering lights, and faulty sound systems caused by worn components or poor connections. Regular maintenance and prompt addressing of anomalies prevent serious problems. Certified Service Centers, utilizing specialized tools and trained technicians, ensure genuine Tesla parts, accurate diagnostics, and standardized protocols, maintaining the brand's reputation for innovation and quality. This guide offers a concise approach to diagnosing and repairing Tesla 12V systems, emphasizing symptom observation, safety precautions, multimeter testing, efficient replacement, and detail-oriented work.

Tesla vehicles, known for their cutting-edge technology, rely on a robust 12V electrical system for various functions. However, like any complex network, it’s not immune to issues. This article explores Tesla’s 12V system, its common problems, and the critical role of certified service centers in efficient repairs. We’ll guide you through understanding the components, troubleshooting faults, and replacing parts step-by-step, ensuring your Tesla remains in peak condition. Learn how these centers leverage specialized knowledge and tools to address 12V system challenges effectively.

- Understanding Tesla's 12V Electrical System: Components and Common Issues

- The Role of Certified Service Centers in Efficient 12V System Repairs

- Step-by-Step Guide: Troubleshooting and Replacing Faulty 12V Components

Understanding Tesla's 12V Electrical System: Components and Common Issues

Tesla’s 12V electrical system is a critical component of your vehicle’s overall functionality, powering essential accessories and components like lighting, audio systems, and certain control modules. Understanding its intricate network of parts—including batteries, alternators, fuses, and relays—is key to effective Tesla 12V system repair. Common issues range from dead battery starts to flickering lights and malfunctioning sound systems, often stemming from faulty connections, worn-out components, or voltage fluctuations.

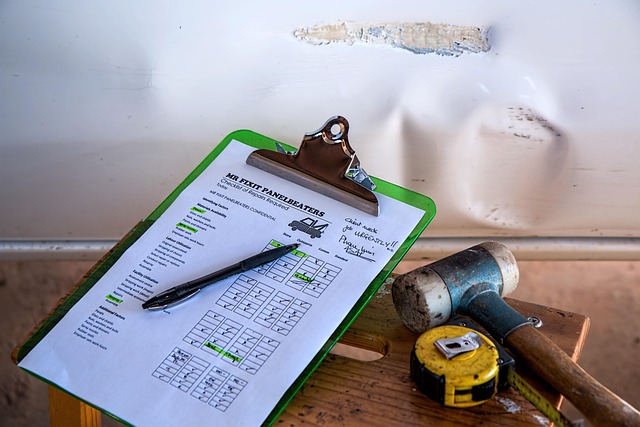

Regular maintenance and prompt addressing of any anomalies can prevent more serious problems. For instance, while services like auto body repair and paintless dent repair might be necessary for external damage, Tesla 12V system repair focuses on the internal electrical backbone, ensuring your vehicle operates smoothly and safely.

The Role of Certified Service Centers in Efficient 12V System Repairs

Certified Service Centers play a pivotal role in ensuring efficient repairs for Tesla’s 12V systems. These centers are equipped with specialized tools and trained technicians who possess the expertise to handle intricate automotive electrical issues. With access to genuine Tesla parts, they can accurately diagnose problems, be it a faulty battery, corroded wiring, or a malfunctioning charging port.

By prioritizing customer safety and vehicle reliability, these service centers offer more than just repair services; they provide peace of mind. Their standardized protocols for 12V system repairs ensure consistency and quality across different locations, mirroring the high standards set by Tesla. This level of professionalism is crucial in maintaining the performance and longevity of Tesla vehicles, contributing to what makes them stand out in the automotive industry—a brand synonymous with innovation and cutting-edge technology like auto body restoration and bumper repair.

Step-by-Step Guide: Troubleshooting and Replacing Faulty 12V Components

When it comes to Tesla 12V system repair, troubleshooting and replacing faulty components is a crucial step for any certified service center. Here’s a straightforward guide for technicians:

1. Identify the Issue: Start by observing the symptoms presented by the vehicle, such as a dim or dead headlight, radio malfunction, or malfunctioning dashboard instruments. These clues will help pinpoint the problem area within the 12V system, whether it’s a faulty battery, alternator, or fuse.

2. Safety First: Before diving into any repair, ensure proper safety protocols are followed. Disconnect the negative terminal of the 12V battery to prevent short circuits and electrical hazards. This step is crucial for both efficiency and auto body repair safety during the Tesla 12V system repair process.

3. Test Components: Use a multimeter to test voltage at each component, including the battery terminals, alternator output, and fuse box connections. Compare readings against known good values. This testing ensures that any replacements are made for faulty parts only, streamlining the collision repair shop’s efficiency.

4. Replace as Needed: Once identified, replace any defective components with genuine Tesla parts or those that meet the manufacturer’s specifications. For instance, if a fuse is blown, install a new one of the correct amperage rating. Remember, proper auto body restoration requires meticulous attention to detail at every step.

Tesla owners can rest assured that their vehicle’s 12V electrical system, despite its complexity, is capable of receiving expert care at certified service centers. By understanding common issues and following a structured approach to repairs, these centers ensure efficient and effective Tesla 12V system repair, minimizing downtime for drivers. With specialized knowledge and access to genuine parts, they play a pivotal role in maintaining the integrity and reliability of Tesla’s electrical systems.